The sevented waste scene improves

Release date:2024-03-11

We know that economic benefits are the foundation of the survival of enterprises and the most important core in the development and growth process of enterprises. With the increasingly complicated business environment of the enterprise, market competition is becoming increasingly fierce, and the development cost of corporate development has continued to rise and the profit is becoming more and more difficult.

"Open source and reducing cost reduction and efficiency" is one of the magic weapons of the current enterprise's survival and development. It is a booster for enterprises to promote precision management, and it is an effective carrier for creating a frugal corporate culture.

It is the main purpose of "throttling" by managing unnecessary resource consumption and expenditure expenditure to achieve economic benefits. As the manufacturing department of the company's operating module, it is the main department of the company. How to save the current is the main problem faced by the manufacturing department. The throttling is not compression, not squeezing, but it saves costs by improving. Improving is not casual, it is planned, planned, and step -by -step improvements. Let ’s take a look at our company’ s “throttling” improvement together.

Improving first requires learning, learning good improvement methods, and good learning concepts can make good improvements. In the manufacturing industry, the TPS improvement of Toyota in Japan is unquestionable. With all the efforts of our company, we are fortunate to be a supplier of Toyota. Fortunately, they have received multiple training from Toyota. Including organizational management personnel to go to Japan Toyota Company to train, participate in TTCC training in Tianjin Toyota, and invite Tianjin Toyota Company to come to the community for professional guidance.

There are many ways to improve improvement from this, and we can improve from many aspects. Among them, the most important improvement method mentioned in the process of Toyota is the seven wastes. The company's seven major waste was used at the scene.

1 Waste of excessive inventory

Definition: Because the inventory of raw materials, semi -finished products, finished products, consumables, and spare parts exceeds the necessary amount, it is a waste caused.

Famous saying of inventory: Inventory is the source of all evil.

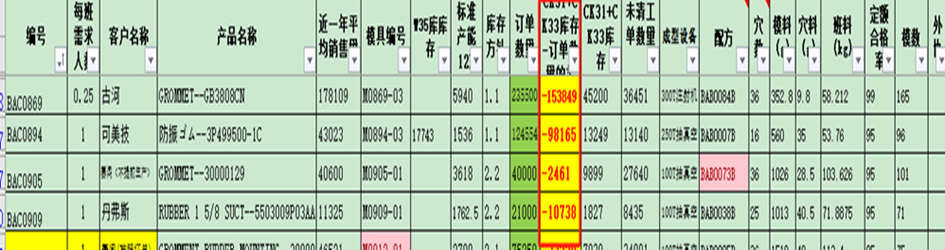

In the second half of 2023, the time and pull -type production models in the TPS we use, which are produced according to customer order requirements to reduce the waste of inventory.

2 Waiting waste

Definition: In the operation, people such as machines, machines and other people, materials and other materials, and other information can cause waste that cannot be moved to the load.

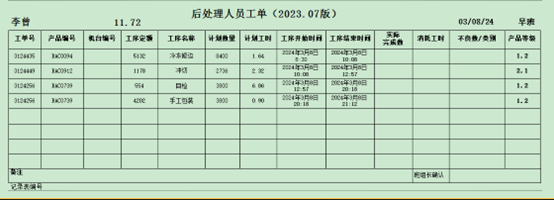

Since 2023, we have carried out lean production, locking the plan one week in advance, and reducing changes in information. Depending on the internal operation time and the outside operation time, the production of one person, two machines, one person, and one person four machines will be achieved, and the waiting and equipment of personnel will be reduced.

Restriction of train timetable

One -person four -machine arranges

3 Waste of action

Definition: The extra beats, extra steps, unreasonable layouts, etc. in the operation cause excess movements.

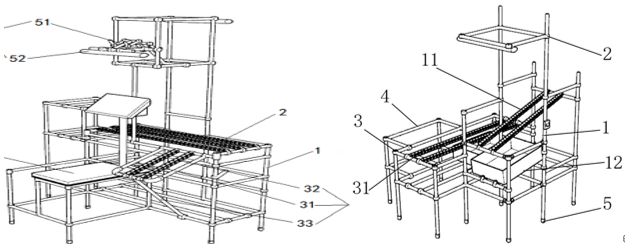

Optimize the layout of on -site operations, according to different products, different personnel, different production and inspection tables, reduce the waste of action taken during the operation process.

4 The waste of handling

Definition: Waste, such as handling and walking caused by two distances in the homework, including people's waste and machine waste.

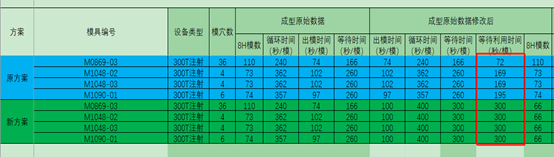

By adjusting the product process route, reducing handling and turnover.

Before improvement:

Improved:

best plan:

5 The waste of bad products

Definition: During the production process, various losses caused by disagreement or manufacturing, the time, manpower and material resources of treatment are required.

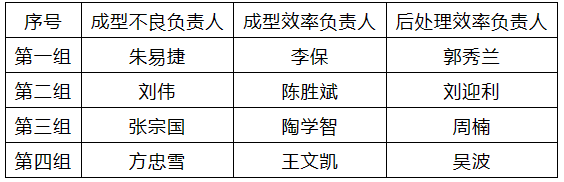

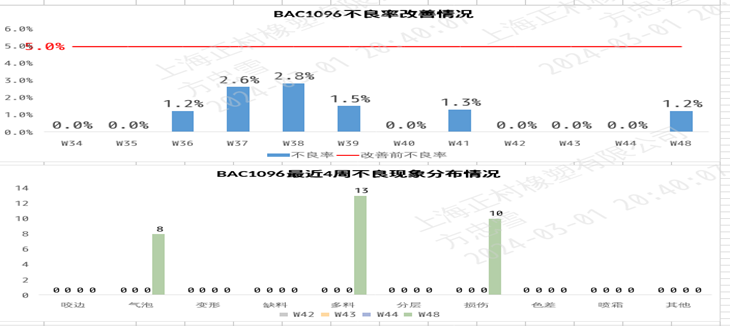

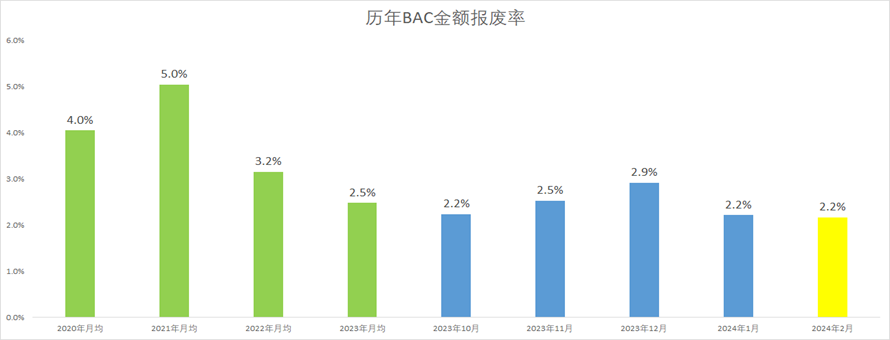

For the poor in production, the TOP30 improvement team is established from the formation to the post -processing process. It consists of technology, manufacturing, and certification personnel. It analyzes and improves adverseness, reduces bad losses, and reduces the scrap rate.

team member

Improvement daily

Monthly summary

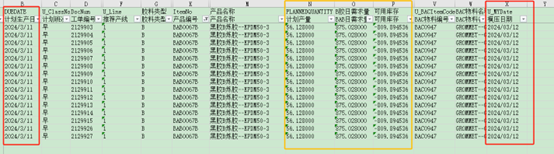

6 Waste of excess production

Definition: Production products that produce more than the next process or the actual needs of orders are produced.

We are produced according to order and minus the inventory in advance according to the demand. This will not be excessively produced.

7 excessive processing waste

Definition: excess process, excess treatment, excess quality and excess processing.

In an environment with fierce market economy competition, we can only survive only than others to achieve more benefits. We must not have the slightest waste. The above briefly introduces the concepts of the seven major waste and some actual use in our company, but the problems and improvement are only the tip of the iceberg, and there are many problems that need to be continuously improved. Follow -up we will participate in all employees to launch the grassroots power. Flexible use of improvement tools to improve the scene. We believe that the company's cost will continue to decline by improving the continuous progress of activities.

Last article:A day can take a thousand miles

Next article:Quality control of the village