A day can take a thousand miles

Release date:2024-01-15

"A day of steps can lead to a thousand miles" comes from the ancient Chinese philosopher Xunzi's "Persuading to Learn", the original text is "no steps, not even a thousand miles; Without small streams, a river cannot be formed." This sentence means that without accumulating a step and a half of the journey, can not reach a thousand miles; Without the accumulation of small flowing water, it is impossible to converge into rivers and oceans. This emphasizes the importance of accumulation and persistence, as long as we make a little progress every day, unremitting efforts, perseverance, we can achieve the goal.

Whether it is in daily life or in work, we always adhere to the belief of "daily steps, can reach thousands of miles", only one step at a time, perseverance, can be successful. Just like the improvement activities of "improving a little bit every day" implemented by Zhengcun, we start from the details, improve a little bit every day, add up to a lot, and one day, there will be qualitative changes.

The implementation of continuous improvement, we mainly from the following aspects

1. Carry out self-explosion activities in management dead corners

By daily self-explosion of the most messy and bad management corners, and improve. This includes not only the cleaning of sanitary dead spots, but also the improvement of some historical complaints. So that the workshop whether in the health environment, or in the daily production activities, have been greatly improved. Through the inspection activities of the dead corners of the management of security risks, the cyclic focus on checking various security risks, always remind everyone that safety is the first.

2, the cost of rubber mixing TOP10 activities

Select the formula with large production capacity and long working hours to optimize and improve, such as optimizing the batching process, mixing process and opening process. For the batching process, we changed the original equipment layout, moved the barcode printer within the operation radius of the employee's arm, and the moving distance of the employee was reduced from nearly ten steps to one step. With a car of raw rubber saves 20 to 30 seconds of operation time, which not only improves the work efficiency but also reduces the labor intensity. And in the mixing process and open refining process, analysis and verification one by one, not let go of every improvement space.

3, full participation in improvement

On the one hand, the on-site improvement plan of the rubber mixing workshop comes from the upper level, such as customer needs and company requirements; A large proportion, on the other hand, comes from front-line managers and employees. In their daily work, they will also put forward some improvement needs, although these improvements are generally not large, but it is precisely these improvements that are the most direct and can best solve practical problems. For example, when the employee slicing rubber A, it is found that the operation of the slicing machine, every two or three cuts, you need to stop, move two or three steps, and operate the cold film machine to load the material, if you want to continuously operate the slicing machine, you need to add a person to operate the cold film machine. The staff proposed to connect the control button of the cold film machine to the control switch of the microtome in parallel, so that it could be operated by a single person.

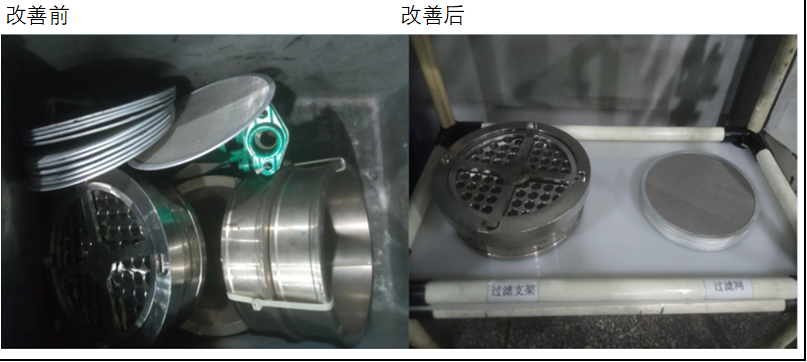

There are many such cases, such as the following aspects of consolidation, the placement of goods and tools, are front-line managers and employees to improve their own behavior.

We can bring in a lot of revenue by improving the equipment and the site. The difficulty of operation has been reduced, the opinions of employees have been recognized, the work has been affirmed, the enthusiasm has been improved, and the ensuing is that our team has been healthy development.

Field improvement is of great significance for enterprises to improve competitiveness, reduce costs, improve quality and safety. Through full participation, continuous improvement and accumulation, the workshop environment and management status have been effectively improved.

Improvement is always on the way. It is because of our persistent determination that we are getting closer and closer to our goal. Small to the rubber mixing workshop, large to the entire company, this continuous improvement activities, so that the company's environment, management ecology, are qualitative improvement, which also laid a solid foundation for the company's long-term development. I believe that in the near future, we will be able to become a leader in the same industry.

Last article:Laboratory layout and prospect

Next article:The sevented waste scene improves