From "Disc Action" to "Waste free Production"

Release date:2020-04-08

"While you need a full meal, why do you need eight treasures and nine tripods? The three meals must be clean." "Grained rice is not easy to be small, so don't take the hard work out of it." Over the past three years, the company's canteen leftovers and leftovers have been slimming down every day. This is due to the consciousness of every employee of the company, and it also reflects the gradual formation of Zhengcun's culture without waste.

In the past, we saw that the canteen chef gave each employee the same food for fairness, and then we saw that many employees ate some dishes and emptied them all. He had been carrying hoe on the day when he was very young, sweat dripping down the soil. Who knows that Chinese food is hard. But when dining in the cafeteria, these have already been thrown out of Jiu Xiaoyun. As a result of such waste, some employees will say that the dish thrown away is not my favorite, the dish thrown away is too spicy, and so on. Perhaps this waste is not just a problem for employees. ,

In order to reverse this situation, the company made two measures:

Build a canteen satisfaction questionnaire, create company menus and canteen recipes. In this way, you can intuitively count the employees 'preferences, and then create company menus and recipes based on the employees' preferences, determine the various dishes that the employees like, and provide food for the employees without repeating the samples every week. Material waste.

2. Reverse the concept and guide employees to take meals as needed. The food intake of each employee is different. In response to this feature, the company guides employees to take meals as needed. This solves the waste caused by the difference in food intake of employees.

3. Cultural promotion. Under the unified planning of the management department, an employee representative sends out a CD photo after each meal, and writes a frugal call to pass to the next employee. Slowly form a culture of waste-free dining.

|  |

The canteen is just a microcosm of the company, and waste-free dining is only one aspect of our Zhengcun people's pursuit of reducing waste. In the production and operation, we put an end to the seven major wastes and use various means to reduce waste and reduce costs.

(The corresponding concepts and influence of the seven major wastes)

七大浪費(fèi) | 真因?qū)ふ?/span> | 對(duì)應(yīng)理念 | 具體方法 | 影響程度 | |

過(guò)量生產(chǎn) | 5Why | 準(zhǔn)時(shí)化 | 可視化 | 批量大浪費(fèi) | |

搬運(yùn) | 標(biāo)準(zhǔn)作業(yè) | 影視化 | 堆積小浪費(fèi) | ||

生產(chǎn)不良 | 自働化 | 防錯(cuò) | |||

Among the seven major wastes, two major wastes are overproduction and inventory.

For overproduction, we changed the original production mode and gradually carried out small-scale production. Because the molding of rubber products is an element of temperature, small-scale production will lead to frequent mold changes. After the mold is switched, the mold needs to be heated, which increases the waste of waiting. To solve this problem, our manufacturing department customized a mold heating device. Currently, we are counting the up and down time of each mold to reduce the mold in the equipment for the subsequent Prepare for heating, reducing the waiting time of equipment and personnel.

For the waste of inventory, we have carried out warehouse transformation in 17 years, reducing the warehouse area. At the same time, statistics on the orders of various customers, reasonable production scheduling, reducing inventory time and accelerating the flow of goods in the warehouse have made some achievements, but reducing inventory has a long way to go. Our company is still exploring the way to reduce inventory. In terms of supplier management, the supplier is required to increase the frequency of logistics and make the delivery time accurate to within 4H. At this time, we are still working hard. The short-term goal is to be 100% accurate within 4 hours. After achieving the short-term goal, we Will challenge 2 hours, 1 hour ... In order to reduce inventory waste, our supply chain department and manufacturing department also count the status of inventory materials every week, perform material inventory statistics according to various dimensions within one week, one month, and three months, find out abnormal inventory, and perform corresponding processing Although the inventory has not yet reached our goal, but the overall trend has been improving, I believe that as long as we have been firmly committed to this goal, we will be able to achieve great results in the near future.

|

|

| (External heating device for mold equipment) | (Production line layout) |

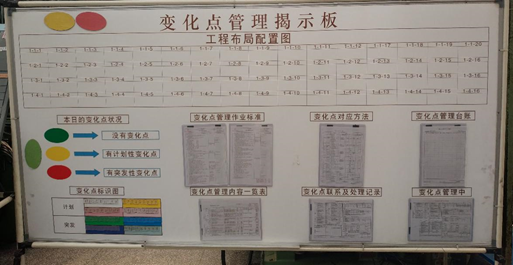

We will not turn a blind eye to the remaining five piles of small waste. We have also made great efforts in the five small wastes. Three years ago, the equipment layout was redesigned. The first phase equipment "five into four", the second phase equipment "two into four", rubber mixing equipment, etc. have been adjusted to make our production layout more reasonable and reduce duplication. Carry and wait. Recently, the relevant departments are planning the relevant layout again for future expansion of production. In the layout planning, they have not forgotten the concept of waste-free production, and have considered transportation, logistics, actions, etc., hoping to minimize waste as much as possible. In production, the operation documents are then subjected to standardized testing to prepare for the subsequent one-man multi-machine and process leveling to reduce unnecessary actions. At the same time, preliminary planning of the video work instruction book, to determine each step, to ensure product quality and improve work efficiency.

(Project layout and change point management kanban)

From the canteen to the production, the concept of no waste has taken root and germinated in Zhengcun. As long as this culture penetrates into the hearts of the people, I believe that the future improvement effect will become more and more obvious. Reducing waste and reducing costs can better serve customers and strengthen their own quality and cost competitiveness. We are already on the road to wasteless production. Although this road has a long way to go, we will never stop and will continue to explore and advance on this road. Reduce waste, improve quality, and serve customers.

Last article:On the Principles and Flexibility of Work

Next article:New starting point, new journey