5S- The best sales clerk of factory

Release date:2017-11-30

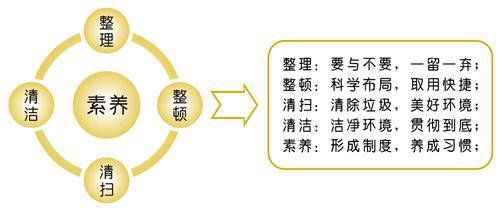

5S management refers to the effective management of personnel, machines, materials, methods and other factors of production in the production site, which is a unique management method. To carry out activities with the contents of sorting out, reorganizing, cleaning up, cleaning and literacy is called "5S" activities.

With the continuous expansion of the company's business, Zhengcun leaders realize that 5S is the best salesman, because an enterprise with a clean, tidy, safe and comfortable environment and a well-educated workforce can often win the trust of customers. For this reason, the company hired Japanese Toyota Kondo Teacher to guide, hoping to further consolidate the internal management basis with the help of professionals, and comprehensively improve the level of on-site management.

In March 2017, Mr. Kondo came to the company site for guidance and put forward a series of rectification plans according to various problems existing in the production/office site. The idea of rectification starts with personnel awareness, carries out 5S training on a large scale in the whole company, combines various publicity activities, and creates a good 5S atmosphere; and then guides from every door, every window, every tool cabinet and every drawer to realize 5S standardized management step by step. After more than half a year's hard work, 5S finally took root and sprouted in every employee's heart, and produced fruitful results.

1. Setting and positioning all items in accordance with the provisions of the positioning and positioning methods are arranged in an orderly and orderly manner, clearly marked, and the necessary items and non-essential items are separated. Necessary items are listed in the designated position and displayed, and the fixed management is implemented. Don't dispose of the things you don't want, and don't put anything other than necessities in the work area. Depending on the frequency of use of items, frequently used items should be placed in the operating area, and occasionally used or infrequently used items should be placed in cabinets or warehouses and marked. Do not waste time looking for things, improve work efficiency.

2. In the 60 second retrieval operation area, only the items necessary for daily use are left. A separate office supplies collection area is set up for the infrequently used items and shared items. Employees can collect the corresponding items in the office supplies collection area within 60 seconds. Since the implementation of the scheme, the consumption of office supplies has been reduced by 30% - 40% compared with the past, and the cost of enterprise expenses has been reduced to the greatest extent.

5S standardized management is not limited to the rectification of office area, but also implemented to the production site. After more than half a year's efforts, the adverse phenomena in the production site have been thoroughly improved. In the past, because of the existence of impurities such as dust, hair, oil, etc., the quality of products will be affected. After the implementation of 5S, cleaning and cleaning will be guaranteed. Certificate, the product is formed, stored and delivered to customers in a good hygienic environment, and the quality is more stable. Through the implementation of 5S, the workplace is clean and tidy. Employees'enthusiasm for work has increased, loyal customers have also increased, and the reputation of enterprises has been constantly high, thus expanding the reputation and sales of enterprises. After more than half a year's rectification, the company's environment has taken on a new look, which has won unanimous praise from both old and new customers. With the continuous expansion of market business volume, 5S work has contributed a lot, which perfectly explains what is "the best salesman".

Last article:R&D and Dates are the both important

Next article:“Make a little progress every day”,is assistant of corporate culture